Operation under extreme climatic conditions

In times when high productivity and fast handling of goods is required in order to minimise costs, the loading and unloading of ships is becoming increasingly important. Engineers are called on to produce ever more flexible and cost-effective systems. A further demand is placed on manufacturers in cases where top performance even under the most challenging climatic and uneconomic geological conditions must be assured. SMB International GmbH is also subject to such demands: In the Russian region of Ulyanovsk, a new port has been built, and corresponding port transhipment...

In times when high productivity and fast handling of goods is required in order to minimise costs, the loading and unloading of ships is becoming increasingly important. Engineers are called on to produce ever more flexible and cost-effective systems.

A further demand is placed on manufacturers in cases where top performance even under the most challenging climatic and uneconomic geological conditions must be assured. SMB International GmbH is also subject to such demands: In the Russian region of Ulyanovsk, a new port has been built, and corresponding port transhipment facilities are to follow. The dynamic development in Russia in the area of bulk goods transhipment is increasing the need for efficient loading and unloading

systems. As a leading provider of such systems and with the necessary foreign experience, SMB has obtained an order

to design and build a ship loading system for cement at the new port.

The Ulyanovsk region lies in the region of the middle Volga, in the central part of European Russia. The total area of the region is about 37 300 million km2. About 1.5 million people live in this region, around 700 000 of them in the centre. The production specialists available here have a characteristically high level of professional training. The region is traversed by important airline, rail and road routes from all parts of Russia. The extent of the railway lines in the region amounts to a total of 729 km. The longest tradition however is that of transport by water.

The Volga flows through the region for a distance of more than 200 km, with tributaries into five lakes. A new port was recently completed here. The region has a well-developed raw material base. The reserves of mineral resources include crude oil, combustible peat and shale. There are also major deposits of cement, construction-, glass- and moulding sand, expanded clay, diatomite and raw materials for bricks. The land resources of the region amounts to a total of 3.7 million hectares, of which 59 % is devoted to agricultural use. The forested area covers 946 200 hectares. The Ulyanovsk region is located in a class 3 earthquake zone, the ambient temperatures range between 35 °C in summer and down to –39 °C in winter, with maximum wind speeds of 108 km/h. With a moderate continental climate, the annual rainfall is around 620 mm.

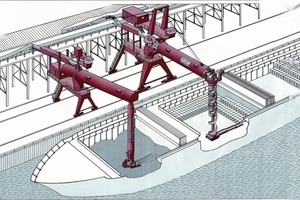

The SMB experts had to come to terms with these climatic conditions with a stable and robust system which would withstand the weather for years to come. Supply interruptions and breakdowns would lead to substantial additional costs. Various parameters play a decisive role in the selection of equipment for ship loaders, such as the location of the system, the type of product supply and the loading throughput. The company decided on a combined system for material in bags

(Figs. 1–2) and bulk, with a construction height of 70 m above sea level. In order to remain as flexible as possible in the loading of ships, SMB installed a mobile loader running on rails

(Fig. 3). The combination of the movements of the loader along the ship and the vertical and rotational movements of the boom enable the optimum loading of a wide range of ship types and sizes, with the greatest possible cost saving. “We meet the demanding technical material requirements of bulk goods transport, as in the bagged goods area, by the use of high-quality components and with a high quality manufacturing standard. The result is highly capable transport solutions which are designed for smooth, long-term operation, and which work with the minimum energy requirement”, explains Dipl. Ing. Andreas Wolf, mechanical engineer of SMB International GmbH. The loading product is cement PZ 500D0 to GOST/3500 cm²/g and PZ400 D20 (20 % additive, for example slag)/3000 cm²/g in bags or bulk. The bulk density of the product, which is abrasive, corrosive and hygroscopic, is 1.2 to 1.5 t/m3 at a maximum temperature of 50 °C.

For bag loading, the material is fed to the loader from the warehouse of a factory by an 80 m long conveyor belt, which first arrives at the tripper car. This takes the bags via a belt curve and a portal conveyor belt on to a central rotary platform, which transports the bags onto a further conveyor belt on the boom. From there the bags continue on to the spiral loading chute, where they slide vertically, due to the force of gravity, onto the rotary platform of a loading head, which guides the bags onto a telescopic conveyor belt of the loading head. By raising and lowering the boom with the aid of a winch drive in combination with a rotary device on the loading head and its telescopic conveyor belt, every part of the ship’s hold can be reached without having to warp the ship. Here the bags are then transported to the designated position in the ship (Fig. 4). This way, and depending on the operator’s skill, 2400 sacks of 25, 40 and

50 kg can be loaded into the ship per hour. The complete loading processes are controlled by a single operator with a radio remote-control and two people who take the bags from the conveyor belt of the loading head and stack them in the hold of the ship.

When loading bulk goods, these arrive first at the tripper car, on which the belt curve is pushed to the side. The bulk cement then falls onto the portal belt, which transports it to a hopper, which is located at the centre of the boom rotation point, and falls onto the boom belt and then into the cascade loading chute. The chute consists of several open cones in an inclined position one above the other, so that the cement “flows” into the ship’s hold, in order to reduce the emission of fine dust and eliminate the risk of dust explosions. Filters are also fitted at transfer points to catch the dust produced. These are cleared pneumatically when full. The loading throughput of such bulk material is 300 tonnes per hour. The power supply is provided by a cable drum attached to the ship loader, and a further copper drum acts as the data line. The cables are unwound from a shaft, which is attached to the quayside belt. During the movement of the loader, it is supplied with low voltage, which is converted by a low-voltage transformer.

The steel construction of the loader was carried out locally in Sengileyev. The material is very thick in order to withstand the local climatic conditions. The relatively small loader therefore weighs 250 t. In order to protect the movement mechanism against ice and keep it warm and flexible, the mechanics use corresponding greases and oils in the gearbox. The electronics of the machine were assembled by SMB in Germany. The motors are produced by SEW, Siemens and Loher, and the switch cabinets and housings were supplied by Rittal. The individual components were constructed in Quickborn. The electronics were supplied in sections and connected at site. For the areas of mechanics, and electronics and programming, the company sends out experts, who coordinate the various working groups at site. All labels and signs are either bilingual in German/Russian or Russian only. “Due to the individual requirements and the challenging environment, our team has gained further valuable experience. The project made a great contribution to improving our contacts in the Russian market and obtaining further information on the industry structures”, in closing

explains Dipl.-Ing. Andreas Heckel, Managing Director of

SMB International GmbH.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.