Change in dust collection technology

The development of PowerCore® fulfils the requirements for an easy and service-friendly maintenance of dust collectors, which has been a demand of the industry for many years: With the incomparably easy filter replacement and the extreme downsizing of the system, the Donaldson engineers have set the standard for an advanced dust collection technology. For a dust collection unit, which up to now had to be equipped with 81 bag filters each of 2.40 m in length, now only 12 PowerCore® filter packs are required (Fig. 1). These savings are based on a single filter changeover. In the calculation...

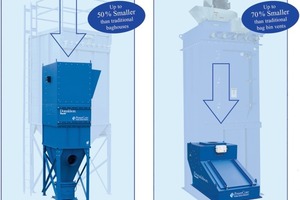

The development of PowerCore® fulfils the requirements for an easy and service-friendly maintenance of dust collectors, which has been a demand of the industry for many years: With the incomparably easy filter replacement and the extreme downsizing of the system, the Donaldson engineers have set the standard for an advanced dust collection technology. For a dust collection unit, which up to now had to be equipped with 81 bag filters each of 2.40 m in length, now only 12 PowerCore® filter packs are required (Fig. 1). These savings are based on a single filter changeover. In the calculation it is assumed that bag filters and PowerCore® filter packs exhibit the same service life. One person can replace a traditional filter bag in 10 minutes, for PowerCore® only two minutes are required. The labour costs are equal to 55 Eur/h. In comparison to conventional dust collectors, the Donaldson units using the new PowerCore® technology are up to 70 % smaller (Fig. 2).

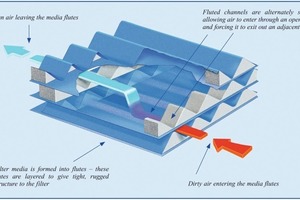

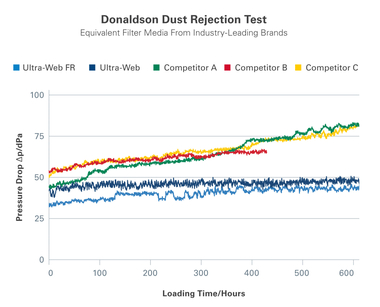

The PowerCore® filter packs combine the latest findings of filter media processing with the patented and proven Ultra-Web® nanofibre technology. The filter media – shaped similarly to that of intake filters – is formed into fluted channels and layered in such a way that a tight, rugged structure is produced (Fig. 3). The rounded shape of the PowerCore® filter packs in conjunction with the patented Ultra-Web® media, traps more dust on the surface of the media flutes than conventional fibre filters such as a depth loading 540g/m2 polyester (Fig. 4).

This innovative technology is a result of many years of research and development with computer-based flow models. Utilizing a directed flow inlet, PowerCore® dust collectors manage airflow and velocities below the filters. The optimized air management technique effectively keeps the bottom of the filter packs clean. It prevents filter abrasion, hopper sweeping and dust re-entrainment. The cleaning efficiency is significantly increased by the new compact oblique impulse cleaning system. The patented system is specifically designed to match the oval shape of the filter packs. The resulting pulse flow effectively covers the entire media pack and easily pulses the dust out of the fluted channels.

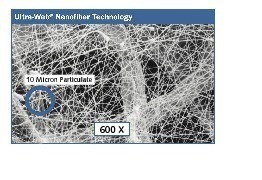

The high filtration performance is facilitated by the Ultra-Web® nanofibre technology. The filter media consists of nanofibres, which are made with an electrospinning process. This production method produces a very fine, continuous fibre of only 0.2– 0.3 micron. From this again a resistant, web-like net with very fine interfibre spaces is formed which are clearly smaller than with conventional filter media. This has the advantage that particles in the submicron and micro range are already held back on the filter surface and not only at the depth of the filter media. The use of the PowerCore® filter packs shows how advantageous this is for the cleaning process.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.