Quality pays off

www.zkg.de/special

The “Warta” cement works (Fig. 1) with an annual production of 1.6 million tons of clinker is one of the biggest plants in Poland (Infobox 1). It is located in the small town of Tre˛baczew in the area of the Cracow/Wielun Jura (Figs. 2a and 2b). Since privatization in 1996, the Dortmund-based Polen Zement Beteiligungsgesellschaft GmbH is the owner of the cement works.

In 1996 it was decided to modernize line 5 by means of a conversion from the wet to the dry process. Within the framework of this modernization the preheater tower was rebuilt (Fig. 3), a vertical roller...

www.zkg.de/special

The “Warta” cement works (Fig. 1) with an annual production of 1.6 million tons of clinker is one of the biggest plants in Poland (Infobox 1). It is located in the small town of Tre˛baczew in the area of the Cracow/Wielun Jura (Figs. 2a and 2b). Since privatization in 1996, the Dortmund-based Polen Zement Beteiligungsgesellschaft GmbH is the owner of the cement works.

In 1996 it was decided to modernize line 5 by means of a conversion from the wet to the dry process. Within the framework of this modernization the preheater tower was rebuilt (Fig. 3), a vertical roller mill, type MPS 4200, from Gebr. Pfeiffer AG as well as a pendulum cooler from the company IKN were installed. Thus, the capacity of the kiln was increased from 1500 to 2700 t/d and heat consumption was reduced to a level of approximately 780 kcal/t. The modernized line was commissioned in 2000. In 2007 the upgrade of line no. 6 was started. The aim was to increase the capacity to 3000 t/d with a heat consumption of approx. 750 kcal/t. The following new equipment was installed: a vertical roller mill, type MPS 4250, from Gebr. Pfeiffer, an IKN pendulum cooler, an ESP from ELEX and a cooling tower from the company Lechler. In 2009 the line was commissioned.

The conversion from the wet to the dry process at the Warta cement works (Fig. 4) in the south of Poland was an unexpected challenge for the maintenance department of the plant. There were significant problems with wear on the fans. After 4 to 5 months the rotors were so worn that a maintenance break became necessary to replace the fan rotors – expensive production downtimes were the consequence.

During the optimization of the fans with regard to the special demands on the wear protection of the rotor, Marek Górnik, plant manager of the Warta cement works, Frank Kolbe, sales manager of Ventilatorenfabrik Oelde GmbH, Leopold Jakubczyk, representative responsible at Ventilatorenfabrik Oelde and Dr. Petra Strunk, editor-in-chief of ZKG INTERNATIONAL, met to discuss the possibilities of optimizing the wear protection based on the specific example of the Warta cement works (Fig. 5).

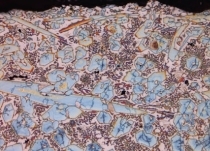

Marek Górnik: In 2000 line 5 was also converted from the wet to the dry process. We then observed a greatly shortened service life of the fans due to wear taking place inside them (Figs. 6a and 6b). At that time, 1997, wear protection of the impellers was provided by chromium carbide with a Rockwell hardness of 60–62. Despite these relatively hard wear protection linings, the service life of our fans only amounted to approximately 4 to 5 months.

ZKG INTERNATIONAL: What was the reason for the much increased wear that suddenly occurred?

Marek Górnik: After conversion from the wet to the dry process, the peculiarities of our raw material deposit became apparent. The limestone extracted is a quartz-bearing limestone rich in SiO2. The higher proportion of quartz and lime and, at the same time, the relatively low content of clay cause increased wear on all process engineering equipment, such as mills, handling and metering devices and also on the process fans (Fig. 7).

Marek Górnik: Together with the specialists from Ventilatorenfabrik Oelde GmbH, we analyzed the problem. At that time Leopold Jakubczyk recommended the use of a new wear protection material consisting of an NiBSi/FTC alloy, which although certainly more expensive, was said to be harder and, consequently, more durable.

Frank Kolbe: Due to the wear pattern on the fan impeller blades, when delivery of a new impeller was planned in 2001, Venti Oelde recommended installing two impeller blades with improved wear protection, i.e. with fused tungsten carbide hardfacing (Infobox 2). This was an opportunity for the specialists at the cement plant to test the new material and to analyze the results.

Marek Górnik: The test run resulted in a much longer service life – about 6 to 7 months compared to 4 months with the former wear protection. Though the material is more expensive, it is worth it, since plant downtimes as well as removal and installation of the rotors require a lot of time and involve a considerable loss of production.

Frank Kolbe: Since then, Venti Oelde only supplies impellers and fans with fused tungsten carbide hardfacing to the Warta cement plant (Fig. 8).

Marek Górnik: Well, that, of course, depends on the availabe raw materials. As already mentioned, our raw materials contain a high proportion of quartz-bearing limestone rich in SiO2, which causes extreme wear. In such cases, fused tungsten carbide hardfacing is recommended as wear protection. The higher price is more than compensated by the longer service life. Finally, I would like to emphasize the support given by Venti Oelde. They did not leave us alone with our problems but gave us the opportunity to test another material so that we could come to a decision about how to further proceed on the basis of our own measurement results.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.