New version of GB16780 brings challenge and opportunity for Chinese cement industry

GB 16780 named “The Norm of Energy Consumption per Unit Product of Cement” is a standard as a guideline for energy consumption, fuel consumption and electricity consumption per unit clinker or cement in China. It proposes the limit data, the level and the calculation method for each consumption. Based on the situation of the implementation of GB 16780-2012, it had been revised from GB 16780-2012 to GB 16780-2021. As a mandatory national standard, it has been published in China by the State Administration for Market Regulation (National Standardization Administration), and will be followed by all Chinese cement plants after November 2022. It provides a guideline for cement plants to improve energy efficiency by new equipment or by using more alternative fuels. The technical indicators are required to be increased by about 5% to 7%. It is also a tool enabling the government to control coal and power consumption via the limit of the standard as well as being beneficial for carbon reduction.

1 Introduction

China is the world’s largest cement producer and consumer. In 2021, China produced a total of 1.54 billion t of cement clinker, 2.363 billion t of cement, while consuming 2.38 billion t of cement, and 1.57 billion t of clinker, including 27.72 billion t of imported clinker, accounting for more than half of the world’s production and consumption [1]. There are about 1600 cement clinker lines in China. From the perspective of carbon emissions, in 2020, China‘s cement industry emitted 1.37 billion t of CO2. According to different studies, the cement industry accounted for 13% of the...

1 Introduction

China is the world’s largest cement producer and consumer. In 2021, China produced a total of 1.54 billion t of cement clinker, 2.363 billion t of cement, while consuming 2.38 billion t of cement, and 1.57 billion t of clinker, including 27.72 billion t of imported clinker, accounting for more than half of the world’s production and consumption [1]. There are about 1600 cement clinker lines in China. From the perspective of carbon emissions, in 2020, China‘s cement industry emitted 1.37 billion t of CO2. According to different studies, the cement industry accounted for 13% of the country‘s total carbon emissions [2]. Therefore, China’s cement industry plays an important role in the world’s carbon neutral pathway.

The standard of GB16780 “The Norm of Energy Consumption per Unit Product of Cement” was released in 2007 as China’s first batch of high energy-consuming product limit standards, and was revised for the first time in 2012 and for the second time in 2021. This standard has been adopted by the Chinese government’s “Twelfth Five-Year Plan”, “Thirteenth Five-Year Plan” and “Fourteenth Five-Year Plan” Comprehensive Work Plan for Energy Conservation and Emission Reduction, “Industrial Green Development Plan”, “Green Manufacturing Engineering Implementation Guide (2016-2020)” and other guidance documents cited. By 2025, the national energy consumption per unit of GDP would drop by 13.5% compared with 2020. Through the implementation of energy saving and carbon reduction actions, the proportion of production in key industries including cement would reach the energy efficiency benchmark level of more than 30%. Energy conservation and consumption reduction put forward higher requirements, which promotes the industrial structure adjustment of the cement industry and the implementation of energy conservation and carbon reduction policies.

As a guideline for energy consumption, fuel consumption and electricity consumption per unit clinker or cement, it proposes the limit data, the level and the calculation method for each consumption. Based on the situation of the implementation of GB 16780-2012, it had been revised from GB 16780-2012 to GB 16780-2021. As a mandatory national standard, it has been published in China by the State Administration for Market Regulation (National Standardization Administration), and will be followed by all Chinese cement plants after November 2022.

2 The main content of the standard

Compared with the 2012 version of the standard, the new version has revised definitions of terms, energy consumption quota indicators and energy consumption calculation. The main contents are as follows:

2.1 Terms and definitions

The 2021 edition regulates the terms of energy consumption and revises the relevant terms and definitions of energy consumption in the standard. The general principles are consistent, and the “comparable” attribute before the energy consumption index is canceled. The value reported by enterprise statistics is taken as the basic value of enterprise energy consumption. The comparable comprehensive energy consumption indicators for clinker and cement were revised to “energy consumption per unit product of cement”, “energy consumption per unit product of clinker” and “fuel consumption per unit product of clinker”, and the term for comprehensive electricity consumption was changed to “electricity consumption per unit product of clinker” and “electricity consumption per unit product of cement”.

2.2 Grade of product energy consumption limit

From 2012 to 2021, the energy consumption quota index will significantly reduce the energy consumption level of the cement industry. If the 2012 version is still used, it will definitely not be able to keep up with the pace of development. Different from the old version, the 2021 version of the energy consumption limit level is defined according to Grade 1, Grade 2 and Grade 3, rather than the limit value, access value and advanced value. In accordance with the newly revised “Administrative Measures for National Mandatory Standards” (issued by the State Administration for Market Regulation No. 25 on January 6, 2020) and the grading requirements for the compilation of a series of energy consumption quota standards, this revision comprehensively analyzes multi-party data and technologies and specifies 5 energy consumption quota indicators. Also, requirements for different enterprises to reach the quota indicators are put forward in the technical requirements.

Compared with the 2012 version of the standard, a lot of research and statistical work on the typical energy consumption indicators of clinker and cement has been carried out for this revision. Based on the data of nearly 900 clinker production lines for analysis and comparison, the total amount of clinker in the surveyed production lines accounts for about 50% of the China’s total clinker output [3]. The analysis results show that the clinker energy consumption values corresponding to 75%, 20% and 5% of the statistical sample clinker production capacity are about 117 kgce/t, 107 kgce/t and 100 kgce/t. If the clinker energy consumption Grade 3 (that is the limit value in the 2012 version) index is determined to be ≤117 kgce/t, about 75% of the production lines with production capacity can meet the limit value requirements, and the remaining approx. 25% of the backward production capacity can be used as the main goal of elimination. If the energy consumption Grade 2 (that is the access value in the 2012 version) index of cement clinker production is determined to be ≤107 kgce/t, the production line with about 20% of the production capacity can meet the requirements, which is the minimum requirements of the energy consumption access for newly built, upgraded or expanded cement enterprises.

Considering the development status of international cement production technology, as well as the energy consumption data of energy efficiency leaders in the promotion and application of domestic “second-generation new dry-process cement technology” achievements [4], and combined with the requirements of national industrial policy planning, it determines the Grade 1 (that is the advanced value in the 2012 version) index is that the energy consumption per unit product of cement is ≤100 kgce/t, and the production line with about 5% of the production capacity can meet the standard. Other energy consumption indicators have also been adjusted accordingly. Table 1 is the comparison of the revised energy consumption index limit value with the 2012 version of the standard. The limit values of Grade 1, 2 and 3 in the standard quota index correspond to the advanced value, access value and limit value of the 2012 version of the standard respectively, and the technical indicators are required to be increased by about 5% to 7%.

2.3 Correction factor

The revision factor is important to the result because it is directly multiplied by the result. It adjusted the correction factor related to the comparable energy consumption of the 2012 version, canceled the “correction factor of clinker strength grade” in the 2012 version of the standard to avoid excessively pursuing high clinker strength caused by the increase in heat consumption, and corrected the high-altitude correction factor. The compilation team investigated 80% of the actual operation data of cement production lines in high-altitude areas. The research indicated that with the continuous progress of production technology, cement production - especially where the calcination process of cement kilns belongs to forced calcination - and the influence of altitude on the production process can be determined by technical measures and the increase in energy consumption of products can be controlled by taking appropriate technical measures. Considering the current production of the enterprise, it is combined with the revised value of the indicators of the high-altitude production line in the second-generation new dry process technology research and the implementation status of the 2012 version of the standard. Because the access requirements for energy consumption products of newly built and renovated and expanded enterprises have been significantly increased, and the current development of cement technology has made targeted optimization and improvement of cement system technology and equipment in high-altitude areas, the altitude correction is no longer performed on the energy consumption access value. The altitude correction is only performed on the energy consumption limit value of the existing enterprises in the high-altitude area, and the adjustment has been made. The altitude correction starting point is set to 1500 m, and the limit value correction does not exceed 5%, as shown in Table 2.

The standard retains corrections for deductions when co-processing or alternative fuels are used, and corrections for changes in cement energy consumption allowances when the proportion of clinker in cement changes. It is especially important for co-processing. Like the 2012 version, in the new version energy such as electricity consumed by co-processing can be deducted from power consumption and, more importantly, the coal saved is not included in the clinker unit. It is an encouragement for alternative fuels technology. Taking a production line with a fuel consumption of 104 kgce/t clinker as an example, when 10% of the fuel is replaced the fuel consumption per unit product of clinker can be reduced to 93.6 kg/t clinker, thus achieving a Grade 1 level. As another example, the heat consumption per unit of clinker in a production line is 3820 kJ/kg (the standard coal is converted to 130.3 kg/t clinker), but because its alternative fuel rate has reached 70% the fuel consumption per unit product of clinker calculated according to the GB16780-2021 is only 38.6 kg/t clinker, far better than Grade 1 level.

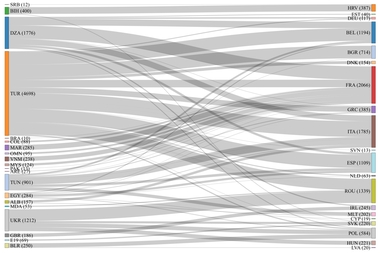

International research associations continue to pay attention to energy efficiency research [5]. The energy-saving measures and carbon reduction path adopted for clinker preparation are similar to those in China [6]. As shown in Table 3 for the thermal and electricity consumption by IEA, it is more advanced in China than other countries and regions [7], however the fuel substitution in China was as low as 2% on average in 2018 [8]. The proportion of alternative fuels in some regions exceeds 50%. The replacement of raw fuels with high harmful components such as chlorine, and the recycling of harmful substances have become research hotspots [9, 10]. Measures are given to handle when the plants use alternative raw materials and alternative fuels [11, 12]. Research aimed at increasing the proportion of alternative fuels while ensuring low energy consumption and high energy efficiency have become the direction of high-quality development of the cement industry [13].

2.4 Calculation method and formula

Combined with the problems existing in the implementation process of the 2012 version of the standard and the feedback from enterprises, the energy consumption calculation formula was revised to be applicable to the comprehensive statistical calculation of multiple energy sources, and the statistical scope of various energy consumptions was standardized by using the energy consumption statistical scope clause. The revision maintained consistency with the requirements of the upper standard. It is stipulated that the calorific value of the fired coal is determined according to the GB/T 213 standard method, namely oxygen bomb calorimetry, the clause for estimating the calorific value of coal according to the industrial analysis of the 2012 version of the standard is canceled, and the accuracy of the calorific value of coal is improved.

This paper selects typical calculation formulas in the GB 16780-2021, including the fuel consumption per unit product of clinker calculated according to Formula 1:

where:

esh the fuel consumption per unit product of clinker, the unit is kilogram standard coal per ton (kgce/t)

n the number of energy types consumed

mi the total consumption of the i-th fuel within the statistical scope of clinker energy consumption, in kilograms (kg)

Qidw the weighted average low calorific value of the i-th fuel within the statistical scope of clinker energy consumption, in kilojoules per kilogram (kJ/kg)

QBM calorific value per kilogram of standard coal, see GB/T 2589, the unit is kilojoules per kilogram (kJ/kg)

Psh The total output of cement clinker required to review GB/T21372 during the statistical reporting period, the unit is ton (t)

Ehe The amount of standard coal converted by power generation per unit of clinker from waste heat recovery during the statistical reporting period, the unit is kilogram standard coal per ton (kgce/t), calculated according to Formula 2:

where:

0.1229 the amount of standard coal equivalent to electricity per kilowatt-hour, the unit is kilogram standard coal per ten million hours (kgce/(kWh))

ωhe the total power generation of the station during the statistical reporting period, the unit is ten million hours (kWh)

ω0 the total self-consumption power generation of the station during the statistical reporting period, the unit is ten million hours (kWh)

The energy consumption per unit product of clinker is calculated according to Formula 3:

where:

Esh energy consumption per unit product of clinker, the unit is kilogram stand ard coal per ton (kgce/t)

Wsh electricity consumption per unit product of clinker, the unit is ten million hours per ton (kWh/t)

Energy consumption per unit product of cement is calculated according to Formula 4:

where:

Es Energy consumption per unit product of cement, the unit is kilogram stand ard coal per ton (kgce/t)

g the average proportion of clinker in cement of cement enterprises during the statistical period (%)

eh the amount of standard coal converted from fuel consumed by the cement preparation system (including cement mixture drying) during the statistical period, the unit is kilograms of stand ard coal (kgce)

Ws electricity consumption per unit product of cement, the unit is ten million hours per ton (kWh/t)

3 Application for cement kiln thermal efficiency

improvement

The revision opinions were proposed according to relevant national industrial policies and new requirements for energy-saving standards in recent years. the data limit is compared in Table 1. Compared with GB 16780-2012, this revision refines the requirements for product energy consumption limits for different types of enterprise. The limited indicators of energy consumption for existing enterprises and new (or expanded) enterprises were decreased by 5% and 5%-7%, respectively. It plays a significant role in government control of coal and power consumption in each plant or area, as well as the plant modification plan for the 14th five-year in China. More and more cement plants are preparing to upgrade existing cement lines by low pressure-loss preheater, larger calciner, new cooler [14], ball mill upgrade [15], roller press, high efficiency fans, digitalization, intelligent measures, AF utilization [16], etc., otherwise they would face the challenge of being shut down because of high energy consumption and carbon emission. In recent years, various mitigation measures have been gaining in importance and the cement industry is shifting more and more to cleaner and low energy production to reduce GHG emissions. Typical references in China are given as the following cases.

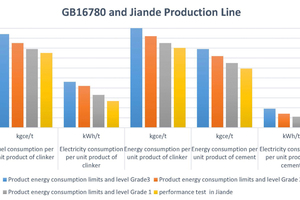

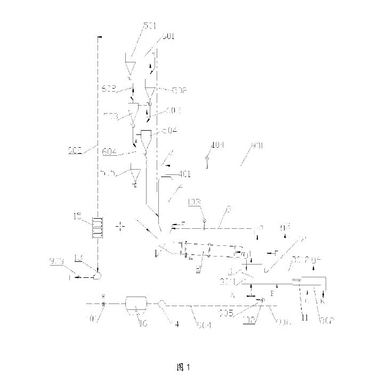

3.1 Jiande production line with a daily output of 5000 t of clinker

The project, located in Zhejiang Province, China, was put into operation in Dec 2021. In order to meet the GB 16780 and keep an advanced level, it integrates the advanced design concepts and technologies in the cement industry. In the performance test, the standard coal consumption of clinker is 93.6 kgce/t.cl, the waste heat power generation is 28.2 kWh/t.cl; the fuel consumption per unit of clinker product calculated by GB16780-2021 is 90.13 kgce/t.cl, 4.1% more advanced than GB 16780-2021 Grade 1 level, the power consumption of clinker is 41.73kWh/t.cl, 13.1% more advanced than GB16780-2021 Grade 1 level, and the energy consumption per unit of clinker product is 95.26 kgce/t.cl, 4.7% more advanced than that of GB16780-2021 Grade 1 level. The clinker strength reaches 61 MPa. Since the project was completed, it has saved 8290 t of standard coal and 10.97 million kWh electricity consumption compared to the Grade 1 level. The annual carbon dioxide emission standard is reduced by 82500 t. As an example for new lines, the completed green and low-carbon smart cement plant has achieved some technological breakthroughs:

First, to save primary fossil energy, it uses a newly developed high-energy-efficiency, six-stage preheater system, gradient combustion self-denitrification calciner, two-support rotary kiln, fourth-generation cooler, and a new type of nanometer insulation material, pulverized coal silo arrangement for stable material flow, etc.

Second, to save power consumption the final grinding technology of raw meal roller press with high-energy-efficiency combined powder separator, double-circle flow cement grinding process, and high-efficiency fan technology were adopted. The power consumption of the cement grinding process is 23.9 kWh/t cement, which is 8.1% respectively compared with the limit of Grade 1 level in GB16780-2021.

3.2 Nanyang production line with a daily output of 7000 t of clinker

It is a basic target for new lines to meet the Grade 1 level in China. However, more than 90% of the existing lines cannot follow Grade 1 level nowadays, better than the Grade 2 level is the most popular target for old existing lines by partial modification. The factory, located in Henan Province, China, was built and put into operation in 2007, and both technical and economic indicators were at a backward level. It implemented the low-carbon transformation in 2021. The contents of the renovation mainly include expansion of the calciner, resistance reduction of the cyclones, replacement of the kiln inlet chamber, new cooler, new kiln burner, and tertiary air duct. Through the 65-day construction period, it has reached the level II energy efficiency limit value in GB16780-2021.

Now the cement system has been operating stably, the product quality has been qualified, the standard coal consumption has been reduced by 5 kg/t.cl, the power consumption of clinker reduced by 5 kWh/t.cl, and the outlet temperature of the preheater has dropped by 30 °C, the outlet pressure of the preheater reduced by 500 Pa, the consumption of SNCR ammonia water is below 3.8 kg/t.cl, and the NOx emission is below 50 mg/Nm3. It has saved 7740 t of standard coal and 6.51 million kWh of electricity in one year, and achieves a CO2 emission reduction of about 28300 t every year, reducing the consumption of ammonia water by 558 t.

4 Future perspectives and final remarks

The GB 16780 standard leads to greater efficiency, higher profitability and improved sustainability. Compared with the 2012 version of the standard, the limit of energy-saving indicators for cement enterprises in GB16780-2021 is increased by about 5%~7%. Through the implementation of the standard, about 25% of the outdated production capacity will be eliminated, or the new standard will be achieved through technological transformation. If it was assumed at least 10 kg of standard coal per ton of clinker had been saved on average on the basis of 1.57 billion t of Chinese clinker output, it is expected that more than 15.7 million t of standard coal can be saved every year. The annual emission reduction of carbon dioxide is about 43.2 million t, and the social and environmental economic benefits of the GB16780 are obvious.

As the basis of the national energy conservation system in China, it is an important means to improve economic quality and efficiency, and to promote green and low-carbon circular development. The National Development and Reform Commission jointly issued the “Guidelines for the Implementation of Energy Conservation and Carbon Reduction Transformation and Upgrading in the Cement Industry”, which requires that by 2025, the proportion of clinker production capacity above the energy efficiency benchmark level in the cement industry will reach 30%, and the clinker production capacity below the energy efficiency benchmark level (that is Grade 1 in GB16780) will be basically cleared. The industry’s energy saving and carbon reduction effect is remarkable, and the green and low-carbon development capacity has been greatly enhanced. By the end of 2020, about 5% of the production capacity in the cement industry had energy efficiency better than the benchmark level, and about 24% of the production capacity had energy efficiency lower than the benchmark level. This means that under the requirements of the GB 16780, nearly 1/3 of the enterprises need to be transformed to meet the standard, otherwise they will be eliminated in the market. The application will promote the optimization and upgrading of the industrial structure of the cement industry and the implementation of the government’s energy-saving and emission-reduction policies, promote the adjustment of industrial structure and eliminate backwardness with energy-saving standards, and comprehensively improve the technical level of energy-saving and emission reduction in China’s cement industry.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![2 Thermal specific energy consumption per ton of clinker in selected countries and regions, 2018 [8]](https://www.zkg-online.info/imgs/1/8/6/6/0/5/9/tok_4b11a1bcd9bd4d12415f135559ecd387/w300_h200_x600_y324_Sustainability_Ma_Jiaomei_Fig_2_m_legende_1-ed1eb182cf0f5a5d.jpeg)