A method for treating lime mud in a lime kiln,

a lime kiln feed head and a lime kiln

(22) 11.07.2024

(43) 06.02.2025

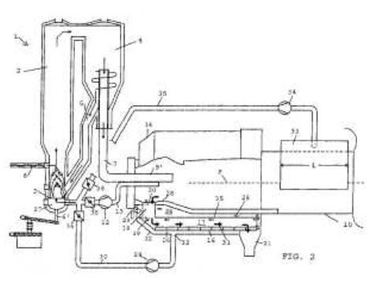

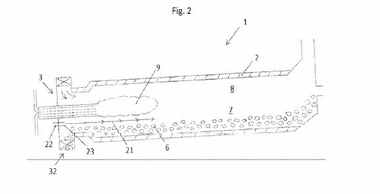

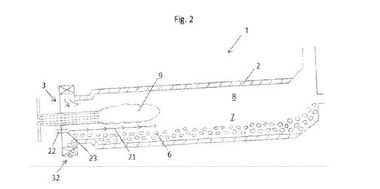

(57) The invention relates to a method for treating lime mud in a lime kiln (2) wherein the lime kiln (2) comprises a rotary kiln shell (10) having an interior space (8) between a rust end wall (6) and a second end wail (11). and wherein the first 5 end wall (6) of the lime kiln (2) comprises a moving wall-part (6a) that rotates with the rotary kiln cell (10) and a stationary wall-pan (6b). and wherein die method comprises method steps of: -feeding lime mud into the interior space (8) of the rotary 10 kiln shell (10) or in close proximity to the rotary kiln shell...

(22) 11.07.2024

(43) 06.02.2025

(57) The invention relates to a method for treating lime mud in a lime kiln (2) wherein the lime kiln (2) comprises a rotary kiln shell (10) having an interior space (8) between a rust end wall (6) and a second end wail (11). and wherein the first 5 end wall (6) of the lime kiln (2) comprises a moving wall-part (6a) that rotates with the rotary kiln cell (10) and a stationary wall-pan (6b). and wherein die method comprises method steps of: -feeding lime mud into the interior space (8) of the rotary 10 kiln shell (10) or in close proximity to the rotary kiln shell (10) by a feeding device (1) at the first end wall (7). -entraining tie I line mud in flue gas flowing out from the interior space (8) of the rotary kiln shell (10) to a separating device (4) through a flue gas riser duct (3), 15 -pretreating the lime mud while the lime mud is entrained with the flue gas stream, -separating the pretreated lime mud from the flue gas stream by the separating device (4), -returning the separated lime mud back to the feeding 20 device (I) and to the lime kiln (2), and -calcining the separated lime mud in the lime kiln (2). In the method according to the ins ention the time mud particles being sticked and/or deposited on the inner surfaces of the lime kiln (2) are detached at least partly 25 from inner surfaces of at least the stational). wall-pan (6b) of the first end wall (6) by a cleaning device (13) provided at the lime kiln feed end (20). The invention relates also to a lime kiln feed head (20) and a lime kiln (2).

(71) Andritz OY; 00180 Helsinki (FI)